Below are some of the terms used to describe gears and their tooth profile. They are used in applications where a right angle gear drive is required.

How Gears Work Different Types Of Gears Their Functions Mechanisms And Applications

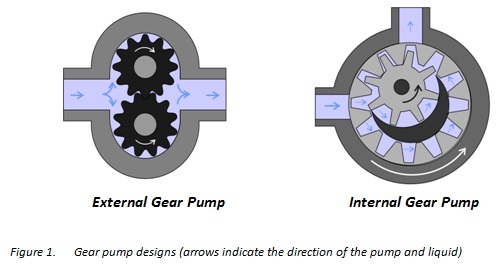

A pair of gears with many teeth external to the gear and called an external gear pump in gear pumps or a few lobes in lobe pumps is demonstrated in Fig.

. Answer 1 of 2. As the pumps motion reduces the size of the space the liquid is forced out. Bevel gears are generally more costly and are not able to transmit as much torque per size as a parallel shaft arrangement.

Internal gears are used for more specific applications such as a planetary gear set. Bypass flow control valves are often referred to as ______________ because of their additional port. Describe the 4 types of fixed cylinder mounts.

Although lobe pumps can be used in pneumatic applications they are typically used in hydraulic applications to move products such as slurries pastes and solids. Bevel gears are most commonly used to transmit power between shafts that intersect at a 90 degree angle. Interlocks are defined as a way to prevent something from happening in a system.

Gears are used in metal cutting machine tools. Positive displacement pumps use pistons diaphragms gears or screws to deliver a constant volume with each stroke. Gears are primarily used in this industry in various types of weapons as well as in other components required for the proper operation of this industry.

Regardless of the load or speed they generally provide smoother quieter operation than spur gears. A disadvantage is the axial thrust force caused by the helix form. There are three major types of planetary gear mechanisms.

Helical gears can bear more load than spur gears and work more quietly. Planetary solar and star types. You need to press on the brake pedal to release the shifter into the drive position to prevent the car from lurching forward.

The rotor is a larger gear and also an inner gear and it has the teeth projecting inside. A _____ motor rotates when hydraulic fluid pressure makes contact with the internal gear at the inlet. In external gears the teeth are placed on the outer surface of the gear body pointing outward from the gear center.

In external gearing if the gears are standard of no-modified addenda interference rarely happens. In this type of gear teeth are cut parallel to the axis of the shafts so when is meshes with another spur gear it transmit the power in parallel shaft and when it connects with the. Internal Gear These gears have teeth cut on the inside part of cones and cylinders and are used to pair with external gears.

An external gear sits inside the internal gear and the gears rotate in the same direction. Because the shafts are positioned closer together internal gear assemblies are more compact than external gear assemblies. Internal gears are often used in applications involving planetary gear drives and gear couplings.

They are also used in applications that require high speeds or high loading. This causes the fluid to move to the discharge port. The short center-to-center distance of using an internal gear set makes it desirable for compact applications.

They are always mated with an external gear with a smaller number of teeth. Internal gears are often used in planetary gear systems. Helical gears are often the default choice in applications that are suitable for spur gears but have non-parallel shafts.

They are widely used in industry. Heat Sensitive Metal Rod. The gapscavities are filled with the fluid during the operation.

However the external gear pump uses two identical gears rotating against each other -- one gear is driven by a motor and it in turn drives the other gear. These are applicable for all types of gears not only bevel gears. Rotary pumps use a variety of means to generate flow.

It is a toothed member designed to transmit or receive motion from another member by successively engaging tooth. The number of teeth of the driver and driven gear are usually different to produce a mechanical advantage. Its a static seal.

An internal gear pump works on a similar principle except the two linking gears sizes are different with one revolving within the other. A gap or cavity is created between these two gears. For bevel gears an internal gear is one with the pitch angle exceeding 90 degrees.

The pump is self-priming. These pumps move liquid by trapping it in the space between the pump elements. On the other hand in internal gears the teeth are placed on an inner surface of the gear body pointing inward towards the gear center.

Internal gears have teeth formed on the inner surface. Today we will describe most important types of it. List and describe the 4 main pump ratings.

Internal gearing is an important part of most of planetary gear assemblies. Gears are used to transmit motion from one shaft to another. Gear pumps may be external internal lobe or ___.

3 port full flow control valve. FAQs basics Featured Gears. Radial and thrust.

A simple example of an interlock is pushing the brake pedal or clutch in your car before shifting it into drive or first gear. Internal means the teeth of one gear are on the inside projecting inward. Internal gear pump consists of two gears off center idle gear and power gears.

Internal gears do not cause output shaft direction reversal. Internal gear definition a gear having teeth cut on an inner cylindrical surface. These gears are used to transmit the power in same plane or when the driving and driven shafts are parallel to each other.

Each gear is supported by a shaft with bearings on both. Name two common methods used in temperature-compensated flow control valves to maintain constant flow as the temperature of the system fluid varies. O-rings are typically used with rotating parts or in equipment that could be exposed to vibration.

Displacement-volume of hydraulic fluid moved during each revolution. External gear pumps are similar in pumping action to internal gear pumps in that two gears come into and out of mesh to produce flow. But in an internal gearing especially in some new types of planetary gears such as the KHV planetary the Y planetary etc 1 various types of interference may occur.

Defense is a very crucial industry as it is associated with the safety and security of the inhabitants of a nation. These are used in shaft couplings which. 14 Helical Gear Helical Gear internal of Gear Motor This is a cylindrical shaped gear with helicoid teeth.

The shaft support as well as close tolerance on both surfaces of gears. The gears rotate in opposite direction to the pump. Conversely an internal gear is one with the teeth formed on the inner surface of a cylinder or cone.

Internal gear An external gear is one with the teeth formed on the outer surface of a cylinder or cone. Internal gear pumps use a gear within a gear design.

Internal Gears Khk Gear Manufacturer

0 Comments